- Home

- Products

Lab EquipmentMore ProductsAnalytical InstrumentMore ProductsConsumablesMore ProductsReagentMore ProductsCustomizedMore Products

- Industry Solutions

- Application Scheme

- Support & Services

- Customer Case

- About Us

- Contact Us

Products

View all categoriesUHPS ultra-high pressure system is developed by RUISHENBAO® and remains the world's first automatic ultra-high pressure pellet press of sample preparation for spectral or X-ray fluorescence analysis, of which the maximum press force can reach 320T so that the press produces high-quality pressed pellets with mirrorlike surface necessary for optimal XRF results. The UHPS achieves the desired homogeneity and stability of each individual pellet with a maximum of reproducibility. There is no dilution effect and effectively it overcomes powder effect of the XRF thanks to direct powder-pelletizing press mode via ultra-high pressure. It greatly improves the analysis of technical indicators for XRF method for example: the detection limit, precision, accuracy and long-term stability. It effectively expands the XRF on the applicable scope for all kinds of samples. The system can be used as an important direct pressing technology and method for sample preparation of the XRF, XRD, laser fluorescence spectroscopy, and laser induced breakdown spectroscopy.

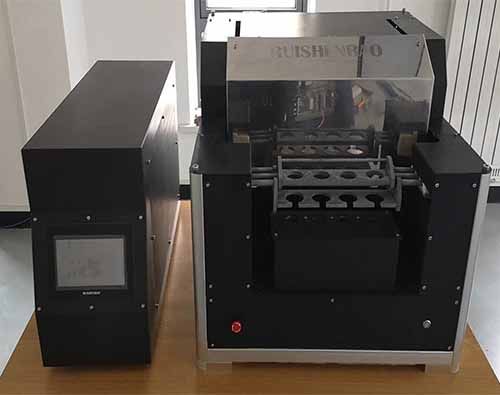

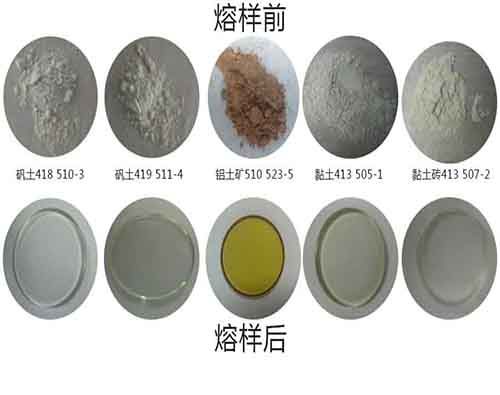

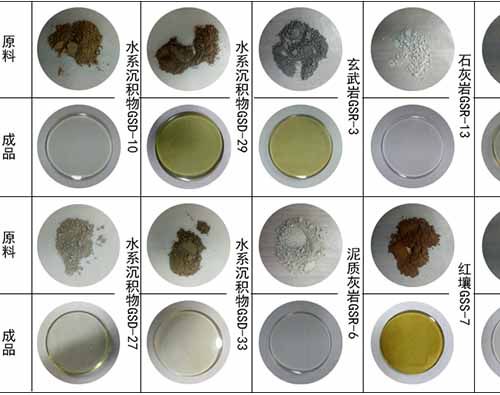

More >MFM-01 Multifunctional fusion, also called multifunctional melting furnace, It is a multi-functional sample making equipment developed by Ruishenbao Analysis Technology (Shanghai) Co., LTD. For X-ray fluorescence spectrometer analysis by glass melting, cast iron remelting and metal remelting. It can also be used for the direct reading spectrum sample pretreatment such as cast iron remelting and metal remelting. It can be used for preparation of molten samples of various minerals, silicates, soils, oxides, metals and nonmetals. The multifunctional fusion is designed for rapid and efficient sample preparation, with high degree of automation, stability and flexible operation characteristics. The machine has rational structure, uses the high frequency induction heating technology, with extremely high heating rate, at the same time equipped with a high precision infrared temperature measurement system with real-time temperature measuring and combined with ruishenbao remains high precision temperature control of proprietary technology to ensure that the molten sample temperature accuracy and reproducibility of the process. at the same time through the selected supporting other system can realize many functions, expanding and pioneering.

More >The FHC-00 high frequency induction fusion is the newly developed by RUISHENBAO® analytical (shanghai) Co., Ltd to prepare glass disks (beads) for X-ray fluorescence (XRF), and solutions for AAS and ICP. Fusion system has been widely used as a necessary device for XRF and AA sample preparation. The FHC-00 combines exceptional fusion accuracy with all the advantages of electric power, more speed, simplicity for experienced, and novice user. It has some features, like good repeatability, flexibility, high precision, short sample preparation time, cleaner, more reliable, low cost and so on. This fusion has two sample positions that it is designed to manage up to 2 samples at the same time with the same control unit, or each one of the sample position can work synchronized in a completely independent manner, with different programs. It effective both in high and low temperatures. The FHC-00 is highly automated unit to control and monitor in real time temperature of the fusion process of one or two samples simultaneously by high-precision IR pyrometer and PID thermostatic control. These enables the user to reach high temperatures in just a few seconds and to effectively control the fusion temperature. Meanwhile, the FHC-00 has two cooling systems, two magnetic stirring system to stir solutions, and a gas extraction system. Touch-screen programmable controls for fusion process like flexible setting of melting temperature, melting and cooling time, crucible rocking movement for homogenization of the melt, and flexible setting of melt pouring facilitated by vibration.

More >The HPS series is an entirely new type of automatic pelletizing press for high pressure input developed by RUISHENBAO® Analytical (Shanghai) Co., Ltd to prepare high-quality pellets, which offers the full benefits of program-controlled sample preparation for x-ray fluorescence analysis. At present, the HPS pellet press is the only and first high pressure(>60ton) press of sample preparation for XRF in market. There are two types for your requirement of which the operating pressure is individually up to 100ton and 120ton. A swing-out cross-head makes filling and cleaning of the die quick, simple and safe. A number of pressing variables can be selected, depending on the press tool employed. Precision press tools with a range of diameters and materials permit free pressing. Pelletizing parameters such as total pressing force, incremental increase and decrease of pressure as well as pressure holding time can be easily operated through a touch-screen LCD display. The pressure increase and decrease during pelletizing are controlled so that inner stresses within the sample are reduced. This allows the production of perfect pellets even with complicated sample material. The pelletizing process is controlled by the PLC program. This leads to substantial improvement in reproducibility of sample preparation and consequently more precise analysis results. The HPS pellet press is a high-quality, high pressure, precision and new engineering product with compact dimensions. It produces high-quality pressed pellets with mirrorlike surface necessary for optimal XRF results. It is ideally suited for laboratory requirements.

More >Cast iron remelting machine CIRF-01,is specially developed by Ruishenbao analytical Technology (Shanghai) Co., LTD. For the recasting of cast iron pig iron and other metal material samples. The problem of pretreatment for sample testing of cast iron, pig iron and other metal materials was solved. This remelting machine is easy to operate and the surface of the remelted sample is whitened thoroughly. It is a rare auxiliary equipment for direct reading spectrometers and other instruments to analyze cast iron pig iron and other metal materials .

More >Centrifugal casting machine CCRM-01, is a special equipment for iron remelting, cast iron remelting and metal remelting samples used for X-ray fluorescence spectrometer and direct reading spectrometer analysis by Ruishenbao Analytical Technology (Shanghai) Co., LTD. It can be used for re-melting powder granular and columnar samples (including fe - Ni - Cu - Al - Co - base etc.), It can also be used for smelting formula and internal standard sample. The remoulded samples are cast into a special mold by centrifugal rotation, During the process, vacuum can be selected, protective gas can be injected, etc. The whole process is fully automated, and the high-quality samples produced are bubble-free, sample is uniform, the process is free of oxidation and loss, and the reproducibility is good. The machine has rational structure, uses the high frequency induction heating technology, with extremely high heating rate, at the same time equipped with a high precision infrared temperature measurement system with real-time temperature measuring and combined with Ruishenbao remains high precision temperature control of proprietary technology to ensure that the molten sample temperature accuracy and reproducibility of the process. Intuitive touch screen design, friendly man-machine interface, simple operation, PLC intelligent control of the whole machine control center, so that it has a high degree of automation, stability and flexible operation characteristics. The design of high frequency rapid heating combined with complete temperature control (optional) motion shake safety mechanism makes the equipment show high efficiency and stability characteristics in the casting sample, with superior performance in various indicators, and also improves the user's operation experience。The material or shape of crucible and mould for this remelter is based on rich experience in producing melting sample equipment and absorbing other advanced and mature experience to select design and production. Some components are selected according to actual needs, which not only saves cost, but also can meet the requirements of different customers for rapid sample making.

More >VGIRM-01 Automatic vacuum inert gas shielded remelting machineis a preprocessing equipment developed by Ruigenbao Analytical Technology (Shanghai) Co., LTD. For direct reading spectrometers and X-ray fluorescence spectrometers. It can be used to prepare various kinds of metal ore oxide ferroalloy rare earth and so on. Equipped with single head or double head melting device, can carry out forward and backward spin swing automatic mold pouring function and centrifugal casting function. It can be used for full automatic melting of metal block or powder materials (including iron base, nickel base, copper base, aluminum base, cobalt base, etc.) under vacuum or vacuum plus atmosphere,It can also be used for vacuum refining and precision casting of alloy steel.

More >The PM-01E is developed by RUISHENBAO® analytical (shanghai) Co., Ltd, which is a new-type dry-mill and specifically designed to offer many practical advantages in all areas in which hard, brittle and fibrous material must be ground extremely quick down to fineness in modern laboratory. It can grind up to 100mL of dry samples per grinding within short time . In this mill, the grinding is performed by horizontal circular oscillations of the grinding set on a vibrating plate. The grinding set consisting of a disc comminute the grinding sample with extremely high pressure, impact forces and friction. The instrument runs steadily and smoothly at maximum speed thanks to the stabilized plane designed. Due to the high end fineness and speed the PM-01E is the perfect mill when it comes to preparing high-capacity and fineness samples for laboratory requirement. The circular vibrations are produced by a frequency controlled and touch-screen programmable controls for grinding cycles. The PM-01E is suitable for the extremely quick, loss-free, high-capacity and reproducible grinding for modern laboratory.

More >Desktop vibratory disc mill PrepM-01BT, is a miniature tabletop grinding and grinding sample making equipment developed by Ruishenbao Analysis Technology (Shanghai) Co., LTD,suitable for different kinds of laboratory samples,such as hard brittleness and dry fiber and other materials such as sample grinding. The grinding tank is fixed on the vibration seat and driven by the vibration motor into circumferential vibration. Under the action of centrifugal force, the grinding tank produces extrusion, impact, friction and shear on the samples in the tank, and the samples are quickly and thoroughly ground. Meanwhile, the samples are uniformly mixed without loss of samples。The whole process was completed in a few minutes,After grinding, the sample particle size is uniform, which can well meet the requirements of XRF analysis on sample size and uniformity. In terms of the performance of the table grinding instrument, it has the advantages of vertical grinding mill, such as working efficiency, sample making performance and labor saving, etc., as well as the advantages of small size. It is well suited to the practical requirements of modern laboratories. The equipment is small in size and light in weight. It can be directly placed on the experimental bench for operation and easy to use.

More >The PM-01XL is developed by RUISHENBAO® analytical (shanghai) Co., Ltd, which is a new-type high capacity dry-mill and specifically designed to offer many practical advantages in all areas in which hard, brittle and fibrous material must be ground extremely quick down to fineness in modern laboratory. It can grind up to 100-500mL of dry samples per grinding within short time (max. equivalent of 500g, depend on feed material). In this mill, the grinding is performed by horizontal circular oscillations of the grinding set on a vibrating plate. The grinding set consisting of a disc comminute the grinding sample with extremely high pressure, impact forces and friction. The instrument runs steadily and smoothly at maximum speed thanks to the stabilized plane designed. Due to the high end fineness and speed the PM-01XL is the perfect mill when it comes to preparing high-capacity and fineness samples for laboratory requirement. The circular vibrations are produced by a frequency controlled and touch-screen programmable controls for grinding cycles. The PM-01XL is suitable for the extremely quick, loss-free, high-capacity and reproducible grinding for modern laboratory.

More >Desktop vibratory disc mill PrepM-01BT, is a miniature tabletop grinding and grinding sample making equipment developed by Ruishenbao Analysis Technology (Shanghai) Co., LTD,suitable for different kinds of laboratory samples,such as hard brittleness and dry fiber and other materials such as sample grinding. The grinding tank is fixed on the vibration seat and driven by the vibration motor into circumferential vibration. Under the action of centrifugal force, the grinding tank produces extrusion, impact, friction and shear on the samples in the tank, and the samples are quickly and thoroughly ground. Meanwhile, the samples are uniformly mixed without loss of samples。The whole process was completed in a few minutes,After grinding, the sample particle size is uniform, which can well meet the requirements of XRF analysis on sample size and uniformity. In terms of the performance of the table grinding instrument, it has the advantages of vertical grinding mill, such as working efficiency, sample making performance and labor saving, etc., as well as the advantages of small size. It is well suited to the practical requirements of modern laboratories. The equipment is small in size and light in weight. It can be directly placed on the experimental bench for operation and easy to use

More >The LPM-01 cryogenic mill with closed liquid nitrogen (LN2) auto-fill system is carefully developed by RUISHENBAO® analytical (shanghai) Co., Ltd, which pulverize and mix some soft, temperature-sensitive or high fat content of samples such as candy, chocolate, Soybeans, peanuts and other food samples for sample preparation in laboratory. The grinding jar is continually cooled with liquid nitrogen from the integrated LN2 cooling system before and during the grinding process. Thus the sample is embrittled and volatile components are preserved. The liquid nitrogen circulates through the system and is continually replenished from an auto-fill system in the exact amount which is required to keep the low temperature of user that evenly reach -196 °C depending on the continuously filling time and amount of LN2. Powerful impact vibratory disc mill results in a perfect grinding efficiency. The auto-fill system avoids direct contact with LN2 and makes cryogenic grinding very safe. Its versatility (cryogenic, wet and dry grinding at room temperature) makes the LPM-01 the ideal mill for quantities up to 100-500 mL (depend on feed material). Its typical area of application includes food analysis, plastic product analysis, mineral analysis, medical aid analysis, drug performance testing, and identification of textile components and so on.

More >Industry Application

View more

Due to the fact that most ferr...

2022-07-15

A large steel enterprise analy...

2022-07-25

Recently, a geological test ce...

2022-07-26Support & Services

View more

X-ray fluorescence spectrometr...

2022-07-26

At present, there are many kin...

2022-07-26

-Cognitive misunderstandings o...

2022-07-26我们产品涵盖实验仪器等行业120个品类,

实验仪器的产销量及品质在中国大陆同类产品中拥有竞争力,远销国际市场。

News Center

View moreCustomer Case

View more