- Home

- Products

Lab EquipmentMore ProductsAnalytical InstrumentMore ProductsConsumablesMore ProductsReagentMore ProductsCustomizedMore Products

- Industry Solutions

- Application Scheme

- Support & Services

- Customer Case

- About Us

- Contact Us

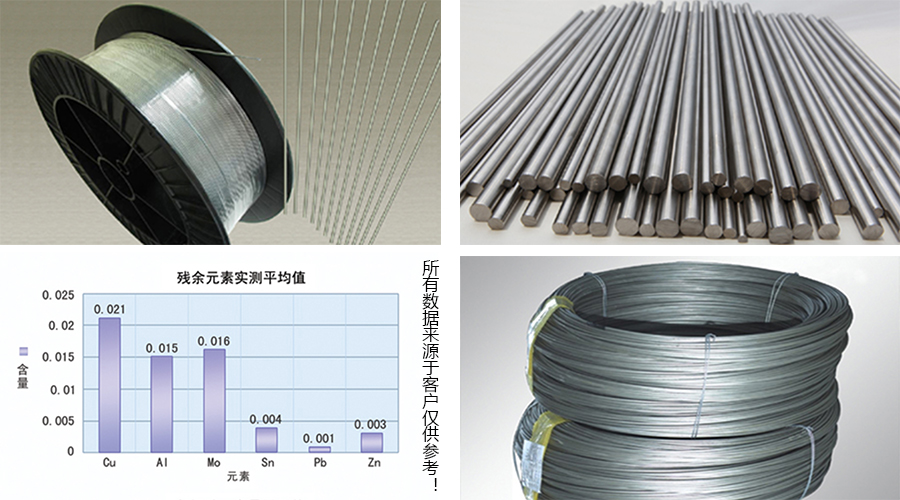

Stainless steel is a kind of blunt alloyed steel that can resist the corrosion ability of air, water, steam, salt water, weak acid solution, etc. Because stainless steel has good corrosion resistance, low temperature resistance, high temperature resistance, no rust, not easy cracking, smooth and flickering appearance, etc., it is widely used in the construction industry, underground pipelines, medical facilities, aerospace, navigation facilities, automobile industry and domestic and civil fields, and is an indispensable material for the national economy and people's life. But in order to identify whether the market sales of stainless steel can meet the requirements of the industry, it must be qualitative and quantitative analysis of the components of stainless steel. Nowadays, there are more than 100 kinds of stainless steel. With the development of stainless steel, there are more and more analytical methods for the chemical composition of stainless steel. In recent years, X-ray fluorescence analysis technology has been widely used in the measurement of stainless steel due to its advantages of fast, nondestructive, accurate, simple operation, reliable results and so on. In X-ray fluorescence spectroscopy, Borate melting sample preparation technology eliminates the grain size effect and mineral effect of the sample, At the same time, the sample is diluted, and the interaction between different elements is greatly reduced, which is considered to be the most accurate sample preparation method in XRF analysis. Due to the fact that most ferroalloys can form cosolubles with platinum at high temperatures, which seriously corrode platinum crucibles, sufficient preoxidation is required. And recently a large stainless steel production enterprise, due to the raw material powder sheet often drop powder, pollution analysis equipment, Change to molten sample preparation, and provide samples to request our help in developing the molten sample method.

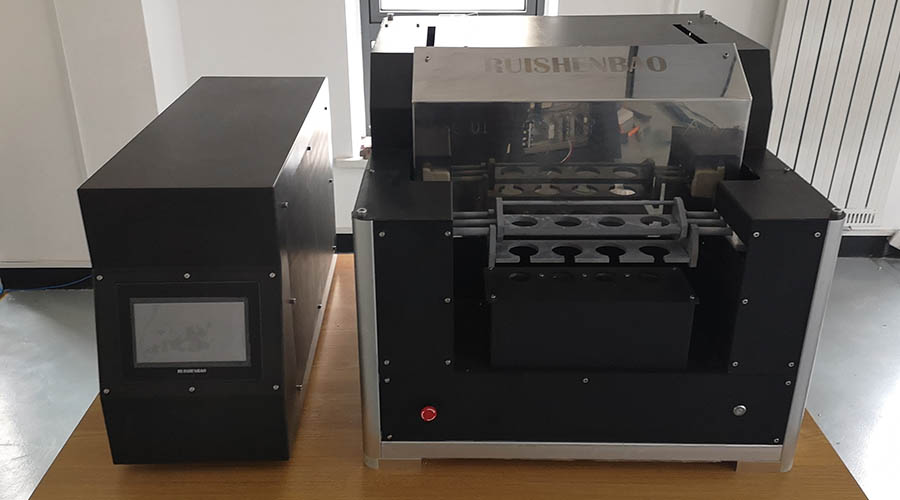

2.1. The equipment

Fully Automated Electric Fusion Machine:FSC-01

2.2.samples:

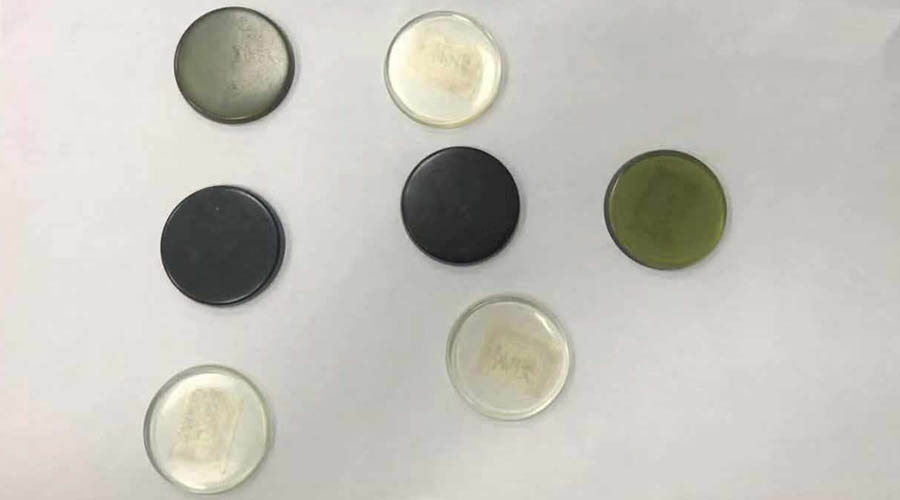

Customer provided samples and named:304B,4Cr10Si2Mo,316LB,21-4N,310S,Martensite protection slag,Austenite protection slag.

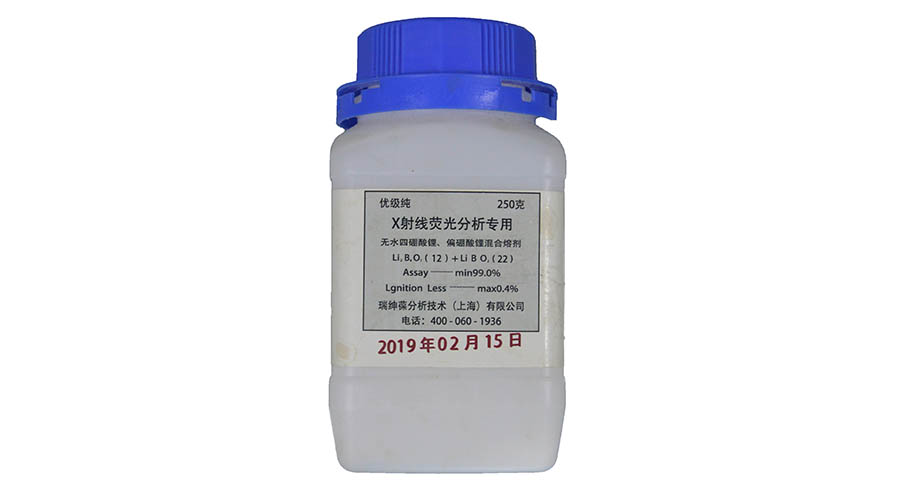

2.3. Reagents:

Mixed flux of lithium borate(Li2B4O7:LiBO2=67:33),Lithium bromide solution(30%)。

2.4. Platinum gold crucible:

Pt/Au: 95/5

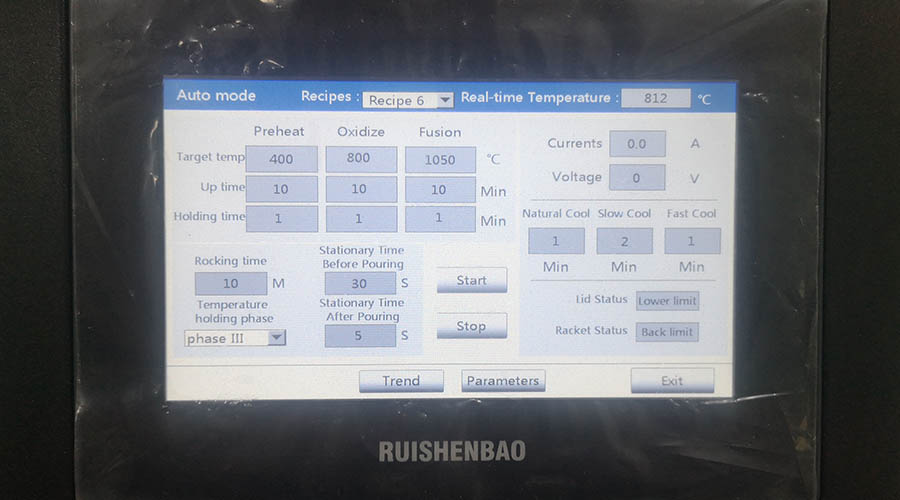

Weigh 9g mixed flux of lithium borate and place it in platinum crucible, then add 0.9g sample and mix well. Add 5 drops of LiBr solution, the prepared sample is loaded into the crucible frame of the molten prototype. Set melting temperature to 1050℃,(The melting temperature of the powder samples of martensite and austenite protection slag was set at 1100℃),The melting time is 7 minutes, the swing time is 10 minutes, the rest time is 30 seconds before dumping and 5 seconds after dumping, and then start running. After the program is completed, the mold containing the sample is taken out and placed on the refractory plate until it is condensed and stripped. Then the sample is labeled and stored in vacuum drying.

Fully Automated Electric Fusion Machine:FSC-01 is an XRF sample preparation equipment developed by Ruishenbao analysis Technology (Shanghai) Co., LTD. The equipment has simple operation, stable performance, wide application range and fast heating speed. The samples produced are uniform and of good quality, which can meet the requirements of customers in different industries for XRF analysis and sample preparation.