- Home

- Products

Lab EquipmentMore ProductsAnalytical InstrumentMore ProductsConsumablesMore ProductsReagentMore ProductsCustomizedMore Products

- Industry Solutions

- Application Scheme

- Support & Services

- Customer Case

- About Us

- Contact Us

All imprints left by geochemical anomalies in the course of deposit formation or disintegration that can be recognized on the basis of the normal or background patterns of element distribution of various natural substances may be called geochemical anomalies. Positive anomalies that are significant in ore prospecting are high element content zones that appear in background patterns. Negative anomaly, the low content zone of elements compared with the background, has been paid more attention and studied for its practical significance in ore prospecting and other aspects. The purpose of geochemical exploration has always been to find ore deposits through the clues of geochemical anomalies. The application of geochemical exploration is gradually expanding. It can not only be used for ore prospecting, but also provide valuable data for solving environmental pollution, agricultural and animal husbandry endemic diseases and various geological problems. Since 1978, China has carried out a nationwide regional geochemical survey, and the regional geochemical data (39 elements) have been used for the secondary development of environmental and human health, agriculture, forestry and animal husbandry. In the new round of land and resources survey (analyzing 76 elements and more indicators), multi-objective regional geochemical prospecting will become an important method.

There are various types of geological samples with different regions and large variations in the content range of each element. Spectrometer analysis such as XRF can well meet the requirements. Currently, various elements of geological samples analyzed by spectrometers such as XRF have occupied an important position in regional geochemical analysis. Recently, a geological test center used The ruishenbao FHC-00 high-frequency induction fusion to prepare geological samples for XRF analysis according to GB/T14506.28-2010 standard.

2.1. Equipment :

High Frequency Induction Fusion: FHC-00

2.2. sample:

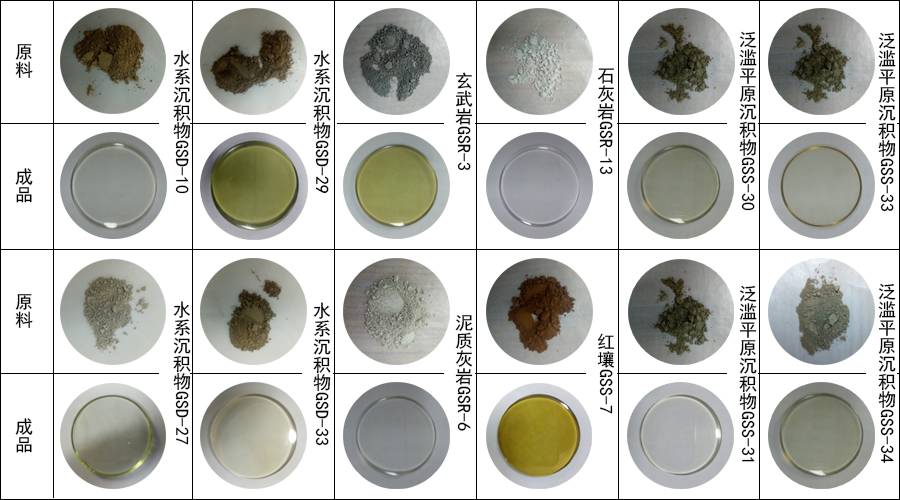

Customer provides samples:GSS-30至GSS-34(Flood plain sediment),GSR-3(basalt),GSR-6(argillaceous limestone),GSR-13(limestone),GSS-7(laterite),GSD-10,GSD-12,GSD-27至GSD-33(stream sediment)

2.3. flux:

Anhydrous lithium tetraborate Li2B4O7,Lithium bromide solution(30%),Anhydrous lithium fluoride,Anhydrous ammonium nitrate

2.4. Platinum crucible:

Pt/Au: 95/5

Calcining anhydrous lithium tetraborate at 700℃ for 2h, drying lithium fluoride and ammonium nitrate at 105℃ for 2h,0.7g of the sample was mixed with 5.2g of lithium tetrabborate 0.4g of lithium fluoride and 0.3g of ammonium nitrate and put into platinum yellow crucible,add 2 drops of LiBr solution. the prepared sample is loaded into the crucible frame of the molten prototype. Set melting temperature to 1150 ,The melting time is 5 minutes, the swing time is 8 minutes, the rest time is 10 seconds before dumping and 10 seconds after dumping, and then start running. After the program is completed, the mold containing the sample is taken out and placed on the refractory plate until it is condensed and stripped. Then the sample is labeled and stored in vacuum drying. Some samples are shown in the figure below:

The FHC-00 high frequency induction fusion can rapidly heat up and cool down through high frequency induction heating to improve working efficiency; At the same time, it is equipped with high-precision infrared temperature measuring system to measure temperature in real time and combined with PID temperature control technology to ensure the temperature accuracy and reproducibility (up to ±1℃) during the melting process, which can meet the requirements of rapid glass melting sample making for different samples.