- Home

- Products

Lab EquipmentMore ProductsAnalytical InstrumentMore ProductsConsumablesMore ProductsReagentMore ProductsCustomizedMore Products

- Industry Solutions

- Application Scheme

- Support & Services

- Customer Case

- About Us

- Contact Us

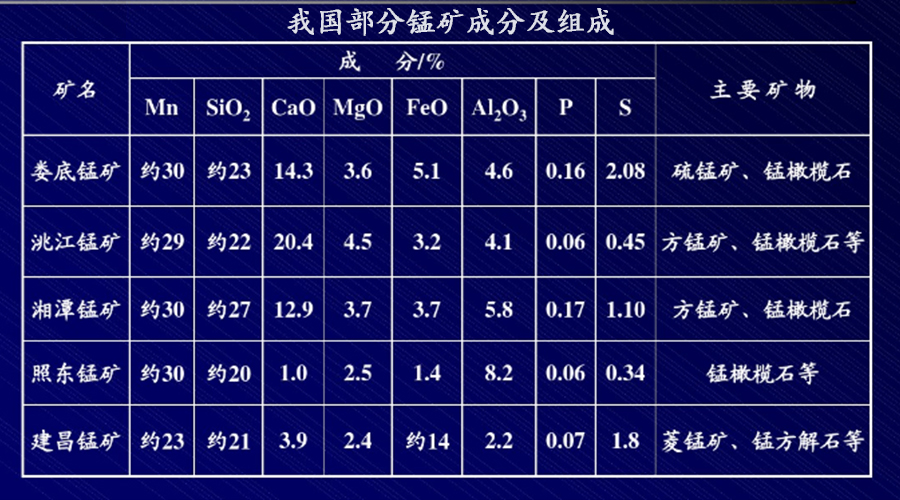

Manganese is a necessary element in the production of all kinds of steel and 90% of the world's manganese production is consumed in the steel industry. As an additive in steelmaking, it plays an important role in the properties of steel mainly in the form of alloying elements. In addition, it can not only be used as deoxidizer and improve the deoxidization capacity of silicon, but also be the main desulfurization element in routine, preventing the hot embrittlement of steel. In China, the output of manganese-based ferroalloys accounts for about 50% of the total output of ferroalloys, with manganese-silicon alloys and high-carbon ferromanganese as the main components, and manganese and medium-low carbon ferromanganese as the auxiliary components (about 8% of the total output of manganese-based ferroalloys). With the progress of steelmaking technology, especially the development of out-of-furnace refining technology and continuous casting technology, the application range of high-carbon ferromanganese, especially the manganese-silicon alloy is constantly expanding. Whether in smelting production or experimental research, it is extremely important to analyze and measure elements such as manganese-iron, calcium, magnesium, aluminum, titanium and silicon in manganese-based ferroalloys. Elements such as silicon, calcium, manganese, aluminum, titanium, magnesium, phosphorus, sulfur and potassium can be detected by wavelength dispersive X-ray fluorescence spectrometer, and elements such as carbon, silicon, manganese, phosphorus, sulfur can be detected by photoelectric direct reading spectrometer. They are important instruments for component analysis and testing of manganese ferroalloy, and a general treatment equipment can solve the complicated problem of sample pretreatment. Ruishenbao was commissioned by a steel plant in Shandong ,province to conduct trial treatment of some samples in the production of manganese ferroalloy.

2.1. Sample making equipment

VGIRM-01 Automatic vacuum inert gas shielded remelting machine

2.2.flux

Pure iron(99.99%)

2.3.Samples

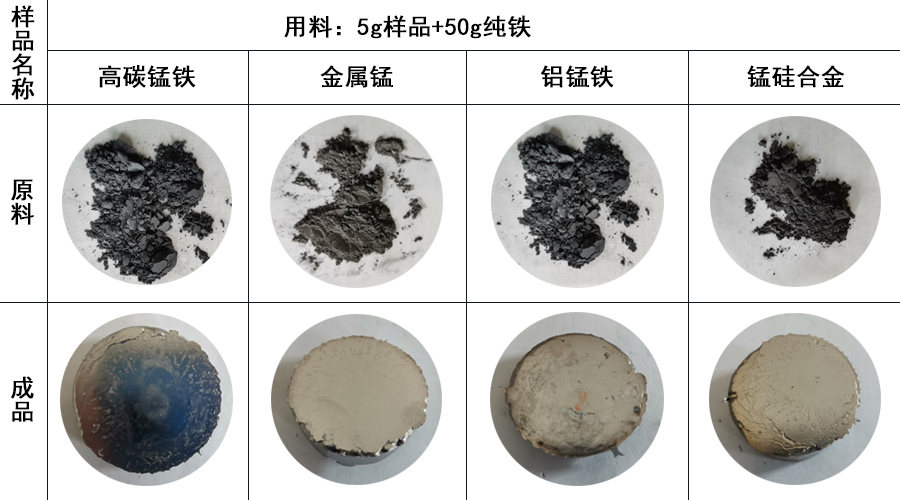

Customers provide products: Manganese metal, manganese silicon alloy, aluminum ferromanganese, high carbon ferromanganese

Take the sample (5 g) and add pure iron (50 g) into the crucible, Argon gas is pumped into the vacuum chamber to reach the set pressure value. At this time, argon atmosphere protection is realized in the heating chamber of the equipment, and the crucible's spin and swing parameters are set:swing speed 5r/min,angle for 30°,rotational speed 5r/min,reversing time 10S;Preheat at 20%, 35%, 50%, 65% power for 2 minutes respectively,80% power melt for 5min(temperature>1400℃),One button start, after the completion of the melting process, casting into the copper mold, rapid cooling. Then take out the block sample, Polish the surface to a smooth surface for analysis.

The remelting furnace equipped with single or double head melting device (spin + swing + inverted mold function + centrifugal casting)。It can prevent burning and oxidation under vacuum or vacuum + atmosphere. It can fully automatic smelting of metal block or powder materials, vacuum refining of alloy steel and precision casting.